- Store & Virtual Showroom

- >

- Paints & Finishes

- >

- Interior Wood Stains & Finishes

- >

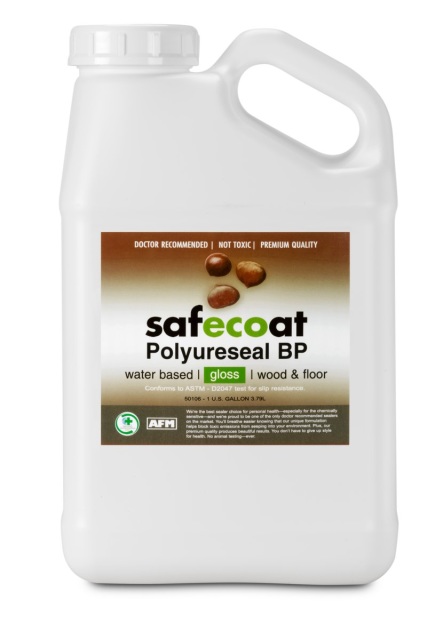

- AFM Safecoat Polyureseal BP

AFM Safecoat Polyureseal BP

SKU:

$129.88

6

638.88

$6.00 - $638.88

Unavailable

per item

Safecoat

Polyureseal BP is one of the highest quality, low toxicity water-based

clear gloss finishes available today. Its exceptional durability and

abrasion resistance, coupled with high solids, very low VOC and low

odor, make it the clear alternative to conventional solvent and

water-based polyurethanes in performance without the toxicity.

Use on: unfinished (or properly prepared and sanded previously finished) wooden surfaces such as floors, furniture and cabinetry, and is excellent for gym floors and auditoriums.

High solids, more film build, better flow, higher luster. Comparable to conventional urethanes in performance without the toxicity.

Fights indoor air pollution, seals in the outgassing from the substrate

Very low VOC content, meets or exceeds all federal and state air quality regulations, including California

Contains no formaldehyde

Safely used by and for the chemically sensitive

Coverage: One gallon covers approximately 350 square feet in one coat depending on method of application and surface porosity.

Use on: unfinished (or properly prepared and sanded previously finished) wooden surfaces such as floors, furniture and cabinetry, and is excellent for gym floors and auditoriums.

High solids, more film build, better flow, higher luster. Comparable to conventional urethanes in performance without the toxicity.

Fights indoor air pollution, seals in the outgassing from the substrate

Very low VOC content, meets or exceeds all federal and state air quality regulations, including California

Contains no formaldehyde

Safely used by and for the chemically sensitive

Coverage: One gallon covers approximately 350 square feet in one coat depending on method of application and surface porosity.

Application: Always have adequate ventilation. Intermix (boxing) all containers of the same sheen to ensure gloss uniformity before applying. Before using, mix coating thoroughly by gently stirring or rolling container to avoid air bubbles. Be sure to stir product thoroughly every 20 minutes during application. Do not shake container. Pour material to be used into another container before applying coating to avoid contaminating main container. Then apply as is, using a quality nylon brush, pad applicator, or unheated spray applicator. Apply liberal coats, keeping a good wet edge and avoid overbrushing. In most cases, a minimum of 3 coats is required, depending on the surface. When spraying, use a .015 tip or smaller. Apply thin even coats when spraying rather than heavy coats which will tend to sag. If spray pattern begins to dryspray, reduce air pressure and increase material flow to surface. Use a damp, dust free rag after sanding to remove dust particles. Use aluminum oxide or silicon carbide sandpaper to sand between coats. For best results, product should not be reduced. Use only during low or moderate humidity conditions. Applying this product over lightly dampened surfaces can assist the user in controlling the dry time. Smoother finishes are achieved when surfaces are damp during application. Note: these instructions are intended to be general only exhaustive. The applicator should determine which preparation and techniques are best suited to the specific surface. Refer to product label for full instructions.

Dry/Cure Time: Under normal conditions, dries to touch in one hour, is sandable after 2-4 hours, and recoatable after 4-8 hours. The product will continue to cure and become harder over time. Avoid traffic for at least 24 hours after application. Normal conditions include a dry surface, access to fresh airflow, moderate humidity, and temperatures around 70 ° F. Thick application, high humidity or conditions other than normal will cause Polyureseal to dry and cure more slowly.

Dry/Cure Time: Under normal conditions, dries to touch in one hour, is sandable after 2-4 hours, and recoatable after 4-8 hours. The product will continue to cure and become harder over time. Avoid traffic for at least 24 hours after application. Normal conditions include a dry surface, access to fresh airflow, moderate humidity, and temperatures around 70 ° F. Thick application, high humidity or conditions other than normal will cause Polyureseal to dry and cure more slowly.

| Spec Sheet | |

| File Size: | 746 kb |

| File Type: | |

| Matte Poly MSDS | |

| File Size: | 147 kb |

| File Type: | |

| Gloss Poly MSDS | |

| File Size: | 472 kb |

| File Type: | |